Things about Electrical Panel Phenolic Labels

Wiki Article

Excitement About Electrical Panel Phenolic Labels

Table of ContentsAll About Electrical Panel Phenolic LabelsExcitement About Electrical Panel Phenolic LabelsSome Known Details About Electrical Panel Phenolic Labels Little Known Questions About Electrical Panel Phenolic Labels.

From: buck [# 6] 6 May 2005 Thanks for the input everyone. I presume the important things I didn't account for was just how quickly the cutters will certainly dull. It's unsubstantiated that you can only obtain around 20 tags from a little bit prior to needing to transform it. Should not carbide last much longer? I will give Capability Plastics a call to obtain a quote on the cutting of the spaces for me.We pay the people about 20c a damaged drill (the drill section is nearly needle slim, breaks promptly) and we walk away with at least 2000 of them - some are 6mm (close to 1/4") in size, With a cutter mill you are in control and can make the appropriate cutter for the right material and do a lot more.

When we sent cutters out for sharpening, they came back with mixed outcomes. Pointer dimensions were usually irregular and a few of the smaller suggestion widths didn't carry out well. That wasn't benefiting me, so the extremely first tool I acquired, was a made use of New Hermes cutter grinder (CG-4).

Having precisely the cutter you require, when you need it? Valuable:--RRB- BTW - I as soon as ran throughout a shop that asserted they make so much money on rotating inscription, they don't have their cutters resharpened.

The Buzz on Electrical Panel Phenolic Labels

You send out in a first-time-sharpened cutter and get back a short stub (Electrical Panel Phenolic Labels). There are some firms that have a background of returning sharp cutters that are the asked for tip dimension, however not the initial cutter that was sent to be honed. What I have actually discovered to do is send this supplier my stubs in hopes of getting some added length as an outcome of the swapPrimarily in my component of the world, contractors wont accept anything preventing phenolics cos they attempted and tested etc. From: Cindy (CINDYM) [# 14] 9 May 2005To: Rodney Gold (RODNEY_GOLD) [# 13] 9 May 2005 Exact same below - if the specs call for phenolic, we need to use phenolic, regardless of just how much we wish we might substitute Romark rather.

Cindy MFrom: Jim (PUZZLEHEAD) [# 15] 9 May 2005To: Cindy (CINDYM) [# 14] 9 May 2005 There are certainly applications where phenolic is the far better item. I have actually located the majority of the time when "penolic" is specified, they only asked for phenolic because they assumed it was a common term for the little engraved plastic tags.

Getting My Electrical Panel Phenolic Labels To Work

9 May 2005 I hear what you are stating, and when we can we do relocate clients to the non-phenolic materials. Many are uneducated, and that is our work - to allow them understand they have options. It appears that nearly all, if not all, our federal government contracts call for phenolic - the specs actually mean it out, so there isn't much I can do about changing them over if that is what the specifications request.

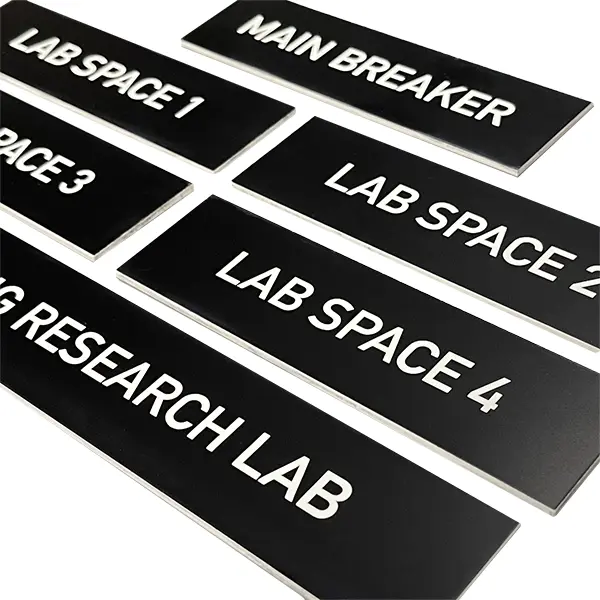

Phenolic is a click here to read non-conductive material (Lamicoid) that is great to use for developing phenolic labels and tags for the electrical sector. The phenolic tags have great characteristics such as resistance to abrasion, heat, and chemicals. Also, phenolic plates function as electrical insulators. Such tags are resilient and have resilient toughness also.

As a result of such factors, Engraved labels have actually found excellent options to utilize for establishing electrical products such as: In case, you need a tag for the electrical button, you should like phenolic plates buttons - Electrical Panel Phenolic Labels. These are trustworthy and risk-free choices for electrical changing requires in markets. The phenolic buttons are long lasting and have low maintenance too.:: As a result of electric insulation residential properties, phenolic tags or labels hop over to these guys are also considered for electric panels

The Of Electrical Panel Phenolic Labels

In most industries, phenolic plastics have an application to construct machine signs as a result of their vibration resistance. Due to such reasons, lots of electrical machines do include phenolic tags to reduce their too much resonance. Phenolic Plates and labels are likewise perfect to use because of their corrosion-resistant building. On contrary, the metal tags are imperfect because of this.

We inscribe numerous of these, we just see this page bill a level rate cost of $ 1. 85, no issue the variety of characters or lines of text. Quantity discount rates naturally apply. 3). What material are Kentron's nameplates made from? Back in the lost days (prior to the '80's or thereabouts) nameplates for the electrical trades were largely made of "Micarta".

There is a large choice of this material to choose from that has actually been particularly created to accomplish exceptional results making use of laser modern technologies. Yes, the manufacturing inscribing product we make use of is UV secure and appropriate for indoor/outdoor applications.

Report this wiki page